Mooring and installation services save time and reduce project footprints, costs and risks for temporary and permanent systems

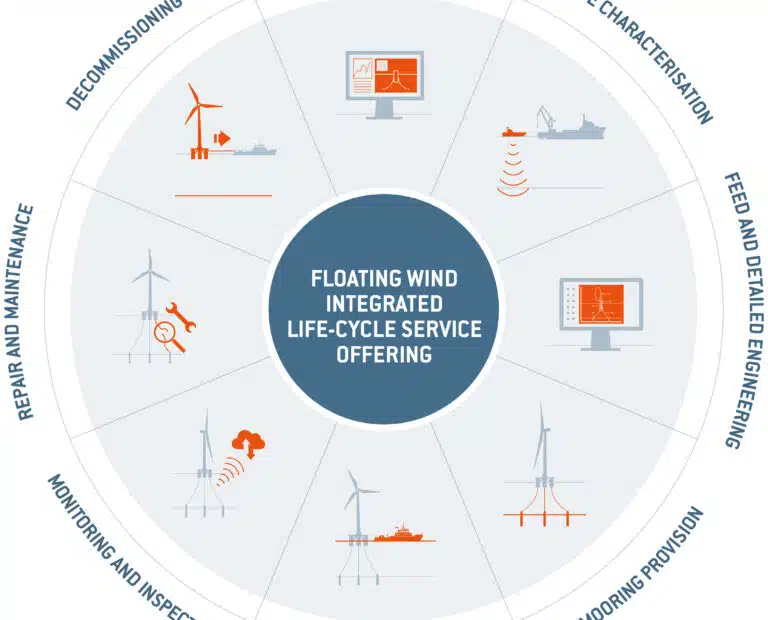

We provide an integrated service covering the entire project lifecycle

Request more infoWe provide an integrated service covering the entire project lifecycle

Request more info

ACTEON IS RECOGNISED AS A GLOBAL LEADER IN MOORING AND ANCHOR LIFE-CYCLE MANAGEMENT FOR FLOATING ENERGY INFRASTRUCTURE

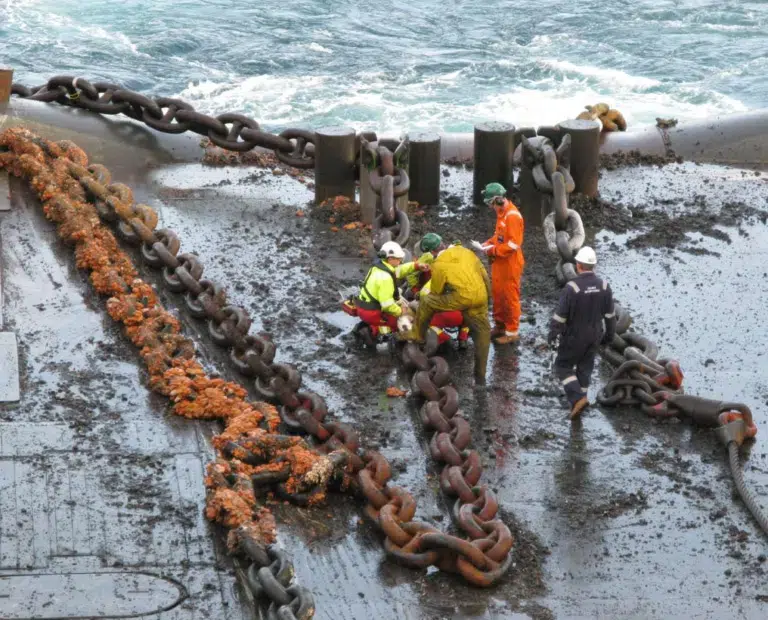

We offer anchor and mooring system construction; marine mooring sales and rental; floating infrastructure positioning and hooking up; mooring installation and inspection; maintenance, repair and replacement services; and late-life disposal services.

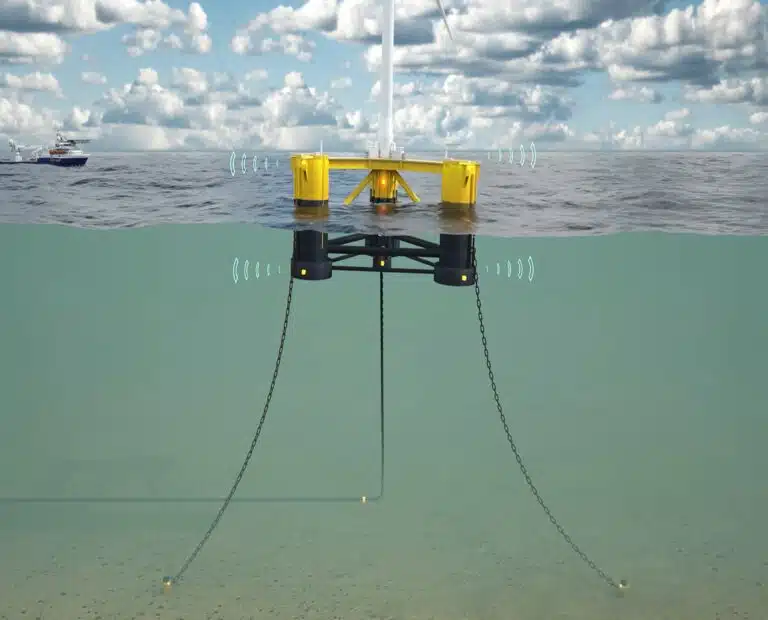

Our track record covers temporary moorings for semisubmersibles, barges and jackups, and permanent moorings for the oil and gas and offshore renewable energy industries. We are building efficient, industrialised solutions for repeatability in floating offshore wind projects.

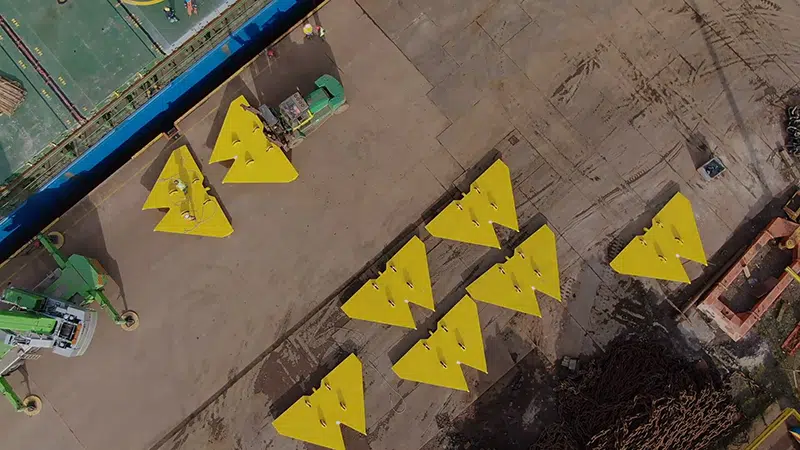

Minimising vessel costs is key to optimising projects. We design bespoke, fit-for-purpose solutions that minimise costs, including suction-embedded anchor systems that enable the deployment of multiple anchors in one sailing.

Costs and risks are also reduced through supply chain procurement expertise, a data warehouse of mooring designs, and domain knowledge that encompasses everything from initial engineering design and marine installation through to asset management and decommissioning.

Our specialisms

The benefits of how we work

A global network with a local focus

Our global network of shore bases provides logistical proximity and project mobilisation capacity for all marine-related activity. These bases ensure fast and reliable access to premium-quality mooring equipment.

Decarbonisation and cost reduction for projects

Our bespoke, fit-for-purpose solutions include a system that enables the deployment of multiple anchors in a single sailing and avoids double-handling mooring solutions.

Custom - built systems for all life - cycle phases

Our lean systems engineering capability and our experience of complex projects that include design, fabrication, integration, installation, commissioning and maintenance ,now extends to floating renewable energy projects.

Moorings and anchors projects

Acteon's Moorings and Anchors segment provides solutions for all types of floating assets, from design and engineering to equipment procurement, installation, inspection, repair and decommissioning.

Our moorings and anchors brands

With joined-up thinking, the brands in our Moorings and Anchors segment combine to offer bespoke solutions to complex challenges.

-

Bruce Anchor is a leading designer and supplier of drag embedment anchors and associated equipment to the offshore energy industries.

-

InterMoor is a world-leader in mooring technology, specialising in mooring assets from engineering and project management to provision of equipment to installation, inspection and repair.

Late-life and end-of-life mooring track record

Access our late-life and end-of-life mooring track record and see which projects have benefited from our mooring integrity services. We offer a worldwide integrated service, including chain inspection, mooring line repair, mooring system data management and analysis, and offshore operations, that prolong the life of floating assets and deliver safe end-of-life solutions.

Latest from this segment

-

Continuing the OEEC discussion: Unlocking the power of floating wind

Offshore Energy Exhibition & Conference (OEEC) is Europe’s leading event for the entire offshore energy industry attended by business leaders, highly qualified experts, and...

Offshore Energy Exhibition & Conference (OEEC) is Europe’s leading event for the entire offshore energy industry attended by business leaders, highly qualified experts, and... -

The Vital Role of Mooring Emergency Response Plans for Floating Wind Farms

Floating wind farms harness the power of wind to produce clean, renewable energy, all while floating atop the ocean. The challenges faced by these farms are as extensive as...

Floating wind farms harness the power of wind to produce clean, renewable energy, all while floating atop the ocean. The challenges faced by these farms are as extensive as...